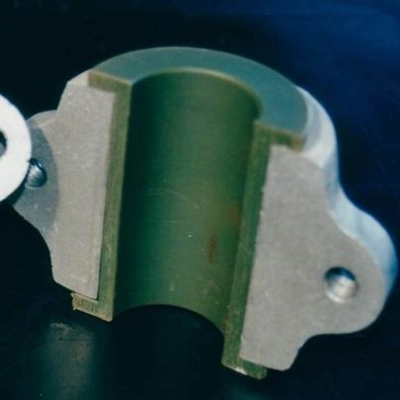

What is a Fibre Composite Vibratory Spring?

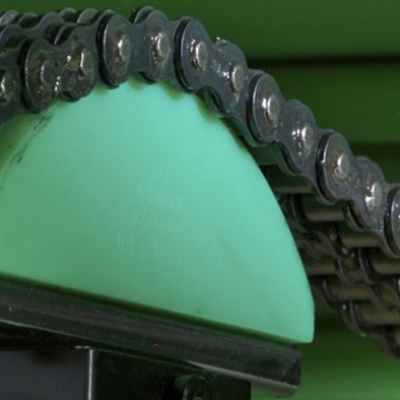

A vibratory spring is a dynamic spring element used in vibratory machinery to support and control oscillating motion. Unlike conventional static springs, vibratory springs are designed to operate continuously under cyclic loading, absorbing and releasing energy as part of the vibration process.

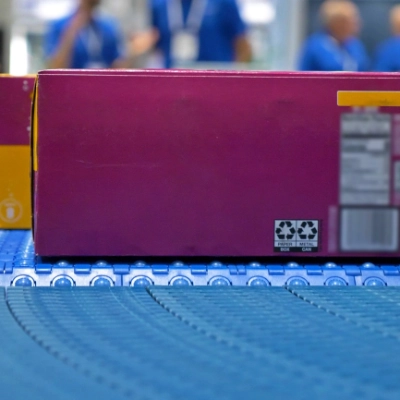

In vibratory conveyors, screens, feeders and sorting equipment, these springs connect the vibrating mass to the stationary frame. When driven by an eccentric motor, exciter or electromagnetic drive, the springs help determine vibration amplitude, frequency and direction. Correctly selected vibratory springs ensure stable material flow, consistent separation performance and reduced stress on machine structures.

Because vibratory systems often operate at resonance, the quality, durability and consistency of the spring elements are critical to overall machine performance and service life.

Benefits of Fibre Composite Vibratory

Springs vs other materials

Fibre composite vibratory springs offer significant advantages over traditional steel and elastomer alternatives, particularly in demanding industrial environments.

Key benefits include:

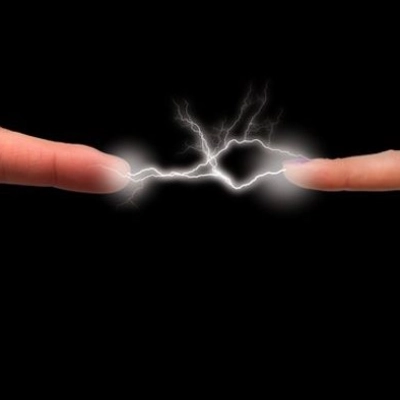

- Exceptional Fatigue Resistance

Designed for millions of load cycles without cracking or loss of performance. - Corrosion Resistance

Ideal for wet, chemical, food-processing or outdoor environments where steel springs may degrade. - Consistent Spring Characteristics

Composite materials maintain stable stiffness over time, supporting reliable machine tuning and performance. - Lightweight Design

Reduced mass improves dynamic behaviour and reduces stress on surrounding components. - Low Maintenance Requirements

No lubrication required and minimal risk of failure due to corrosion or metal fatigue. - Reduced Noise Transmission

Composite materials help dampen vibration and minimise structure-borne noise.

Common Types of Vibratory Springs

materials, each offering different performance characteristics depending on the

application.

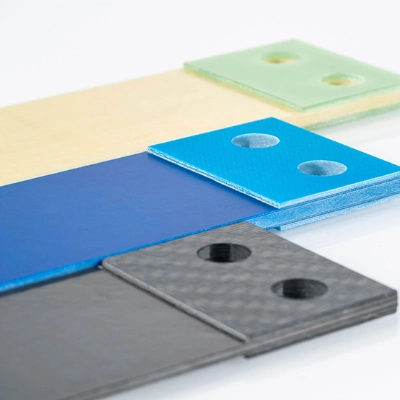

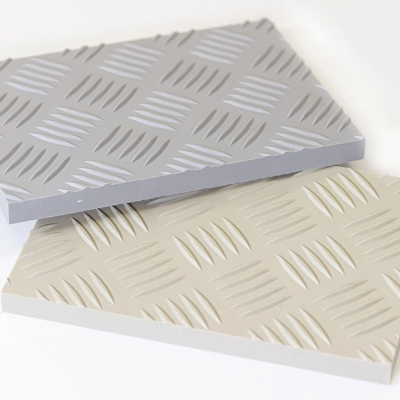

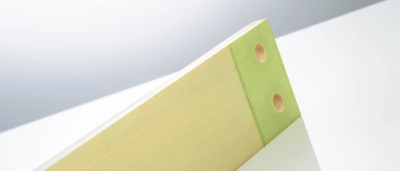

Dotmar supplies fibre composite vibratory springs from the S-Ply® range, including:

- S-Ply Yellow Most Common grade utilised

- S-Ply Yellow HT Higher temperature (160°C) vs Yellow (120°C)

- S-Ply Blue Food grade and visually detectable

- S-Ply Carbon Higher stiffness and load capacity

- S-Ply Carbon Blue Food grade version of S-Ply Carbon