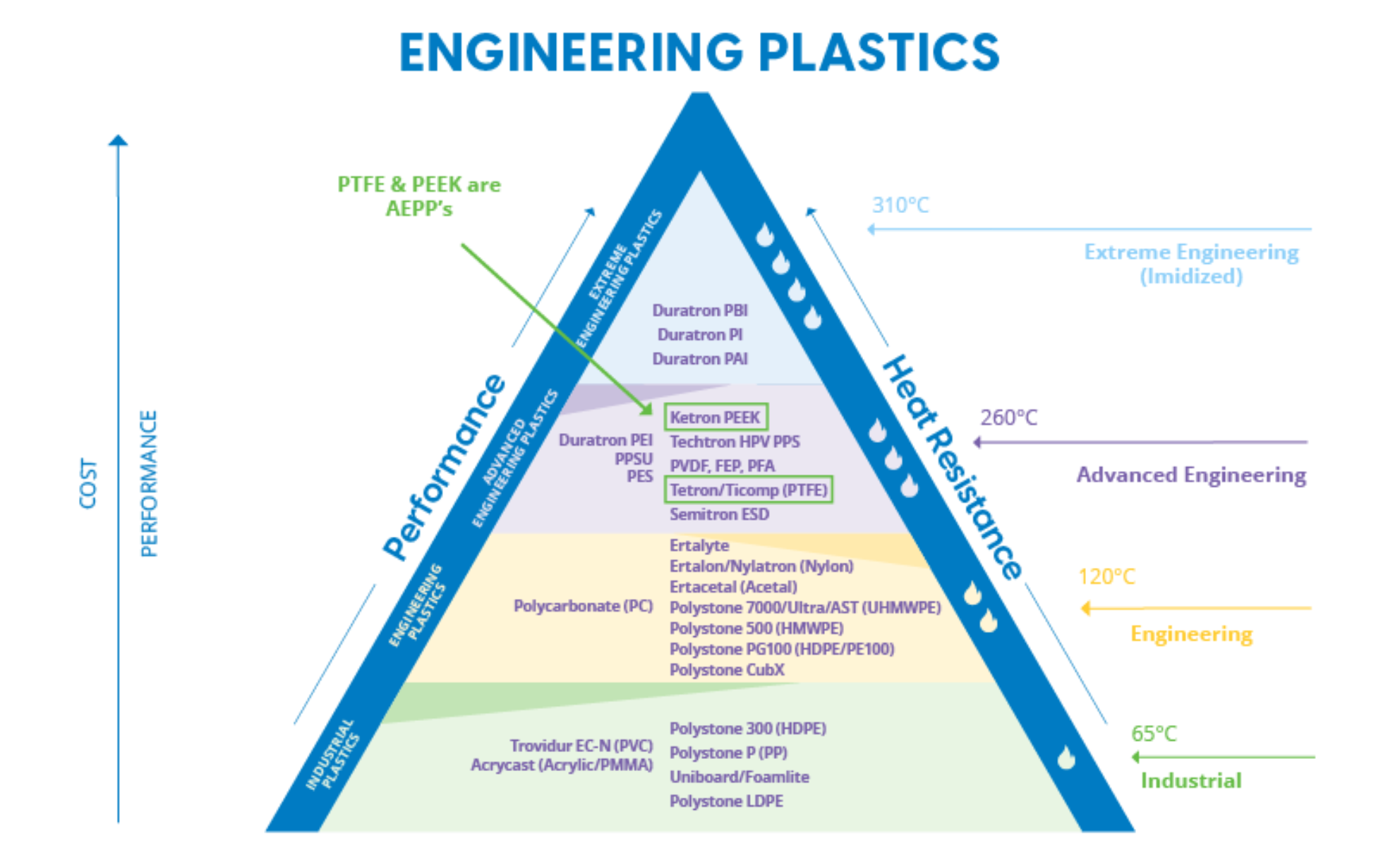

Polytetrafluoroethylene (PTFE), commonly known as Teflon, or under brand names Tetron/Ticomp, falls under the advanced engineering section of the engineering plastics pyramid. PTFE is a synthetic fluoropolymer with high-performance properties such as exceptional chemical and heat resistance, and a very low coefficient of friction. More properties and applications will be explained below.

Key Properties of PTFE

- Non-stick: Lowest coefficient of friction

- Chemical Resistance: Inert to most chemicals and solvent

- Temperature: -200 degrees Celsius to +260 degrees Celsius (broadest)

- Electric Insulation: Best Dielectric Strength 50-60kV/mm

- Naturally UV Stable

- Low Flammability: UL94 V-0

- Food Compliant

Dotmar PTFE Capabilities

Dotmar can supply stock shapes (rod & sheet), custom manufactured parts, and custom sized cylinders.

| Grade | Common Fillers | Description |

|---|---|---|

| Tetron | Tetron S | Virgin, no fillers |

| Tetron G | 25% Glass filled | |

| Tetron GR | Glass/graphite combination filler | |

| Tetron C | 25% Carbon filled | |

| Tetron B | 60% Bronze filled | |

| Ticomp | Ticomp S | Bearing grade/ suitable for food contact |

| Ticomp BG | Bearing grade – better than Ticomp S | |

| Ticomp HVM | Designed for high-speed wear parts | |

| Ticomp MD | Metal detectable blue | |

| Tetco | Tetco V | Melt processable (weldable) – various available. |

Common Applications

- Rotating or pivoting bearings or bushes

- Wear Pads

- Wear strips and chain guides

- Scrapers

- Rollers

- Pulleys & Sheaves

- Gears

- Seals

- Fabricated Parts – tanks or guards

- Spacers or Structural parts

- Electrical insulator

- Flow promotion liner

- Other