What are Plastic Feeding Troughs?

Cattle feeding trough, is a container or channel used for holding food (such as hay, silage, or grain) for feeding cattle and other livestock. These troughs are typically made of durable materials such as metal, plastic, or wood and are designed to withstand the weight and behaviour of the animals. They are usually placed in barns, feedlots, or pasture areas where cattle gather to eat. The design of the trough allows multiple animals to feed simultaneously, reducing competition and ensuring each animal gets its share of the feed. Troughs may vary in size and shape depending on the specific needs of the livestock and the feeding practices of the farm.

Benefits of Plastic Feeding Troughs

Plastic cattle feeding troughs offer several benefits compared to troughs made from other materials such as metal or wood:

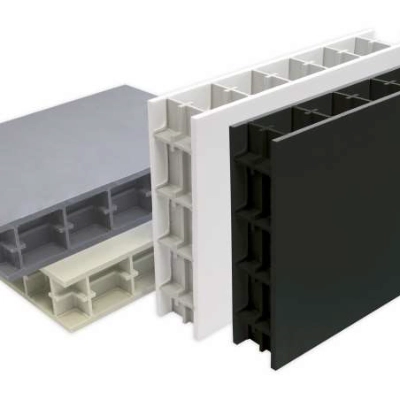

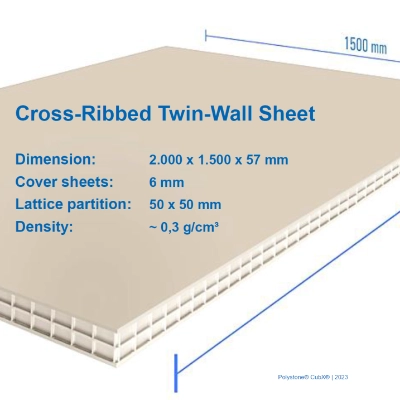

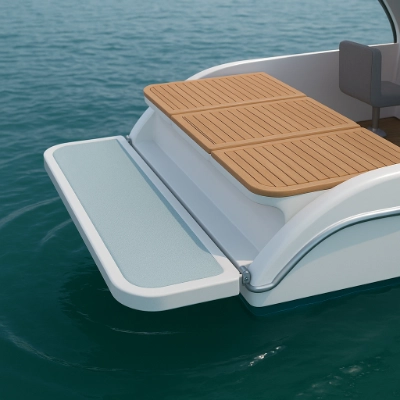

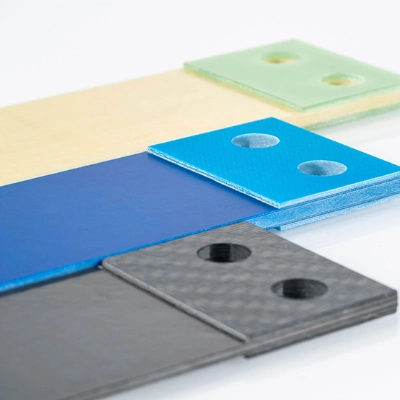

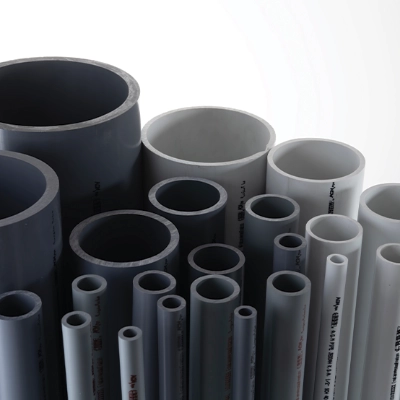

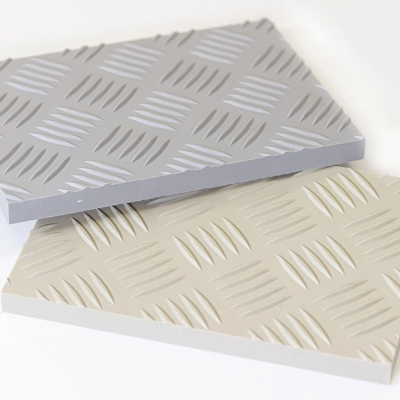

- Durability - High-quality plastic fabricated troughs are durable and resistant to corrosion, rust, and decay, making them suitable for outdoor use in various weather conditions. They are also less likely to degrade over time compared to wooden troughs.

- Ease of Cleaning - Plastic troughs are non-porous and smooth, making them easy to clean and sanitize. This helps maintain good hygiene and reduces the risk of bacterial contamination, promoting the health of the cattle.

- Lightweight - Plastic troughs are typically lightweight compared to metal or concrete troughs, making them easier to transport, install, and move as needed.

- Resistance to Chemicals: Plastic troughs are resistant to chemicals commonly used in farming operations, such as disinfectants and pesticides. This makes them suitable for use in environments where exposure to such chemicals is likely.

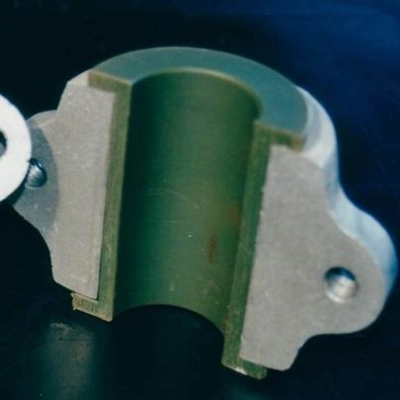

- Reduced Risk of Injury: Plastic troughs are typically designed with smooth edges and rounded corners, reducing the risk of injury to cattle compared to troughs made from metal or other materials.

- Low Maintenance: Plastic troughs generally require minimal maintenance compared to troughs made from other materials. They do not require painting or sealing like wooden troughs, and they do not rust or corrode like metal troughs.

- Cost-Effective: Plastic troughs are often more cost-effective than troughs made from other materials, particularly when considering their durability and longevity. The reduced maintenance and longer lifespan can result in cost savings over time.

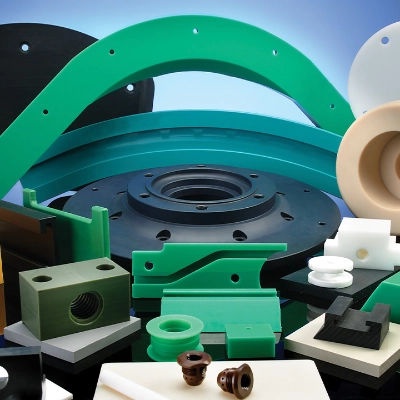

- Customisable – Plastic fabrication allows for one-off designed or sized feeding troughs to suit the individual needs of an application or space.

Overall, plastic cattle feeding troughs offer a combination of durability, ease of cleaning, lightweight construction, and resistance to chemicals, making them a popular choice for many farmers.

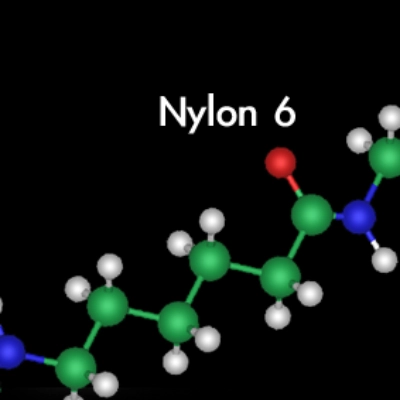

Dotmar has qualified engineers that can provide direct support with material selection for plastic fabricated feeding troughs.