Benefits of Plastic Cattle Crush Boards

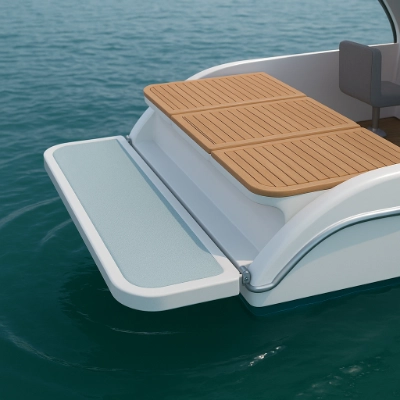

A cattle crush, also known as a squeeze chute or simply a crush, is a cage or enclosure designed to safely restrain cattle for various purposes, such as medical treatment, veterinary examinations, vaccinations, tagging, or other management tasks. It is an essential tool in the livestock industry for ensuring the safety of both the cattle and the people working with them.

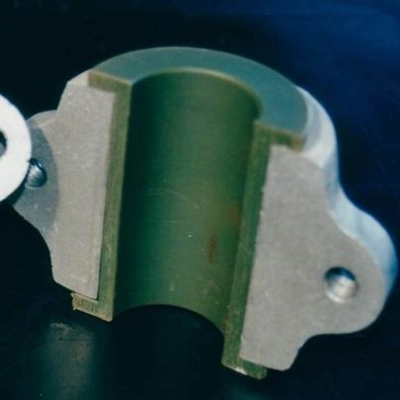

Plastic Cattle Crush Boards are the part of the crush that comes into contact with the animal and is a less harsh material compared to steel to prevent bruising or harming the cattle.

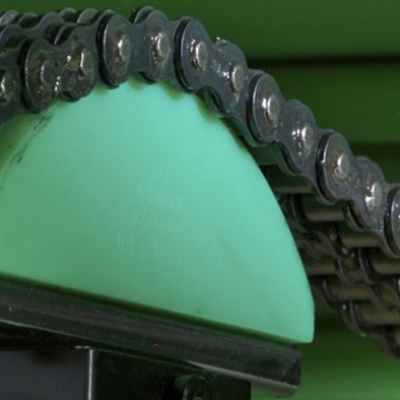

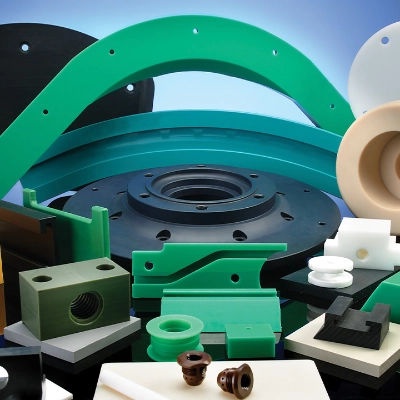

Benefits of Plastic Bushes & Bearings vs Other Bearings

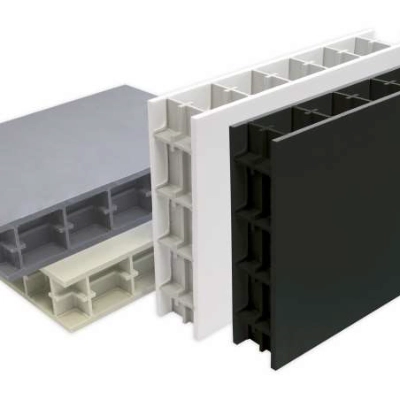

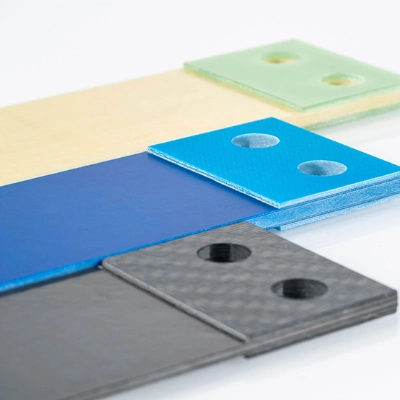

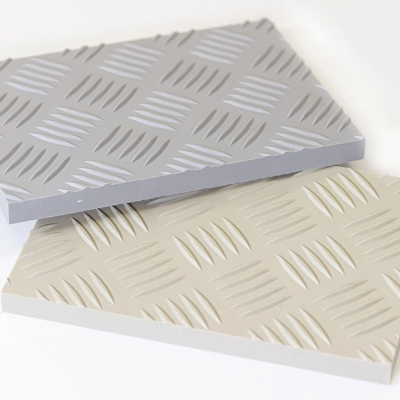

- Non-Corrosive – plastic such as Uniboard / Foamlite won't rust, rot or corrode.

- UV & Weather Resistance – UV stabilised plastics are designed for outdoor use.

- Non-Harsh – plastics are not harsh like steel, therefore aid to prevent bruising or harming the cattle.

Dotmar has qualified engineers that can provide direct support with plastic board material selection.

.jpg?w=800&h=450&crop=true)