Acounting for thermal expansion

The thermal expansion (and contraction) rates of plastics are generally higher than traditional engineering materials, and subsequently, when Checker Plate flooring is subjected to a change in temperature, there are design and installation techniques that need to be taken into consideration to achieve a successful result. This is especially important for larger spans such as flooring.

Design and installation considerations

This table provides the linear thermal expansion of Polystone PG100 Checker Plate under a range of conditions for unrestrained floors.

| Expansion for Various Floor Spans and Temperature Changes | |||

|---|---|---|---|

| Change in Temperature | 1 metre span | 2 metres span | 3 metres span |

| From 20°C to 30°C | 1.5 – 2.3 mm | 3.0 – 4.6 mm | 4.5 – 6.9 mm |

| From 20°C to 40°C | 3.0 – 4.6 mm | 6.0 – 9.2 mm | 9.0 – 13.8 mm |

| From 20°C to 50°C | 4.5 – 6.9 mm | 9.0 – 13.8 mm | 13.5 – 20.7 mm |

| From 20°C to 60°C | 6.0 – 9.2 mm | 12.0 – 18.4mm | 18.0 – 27.6 mm |

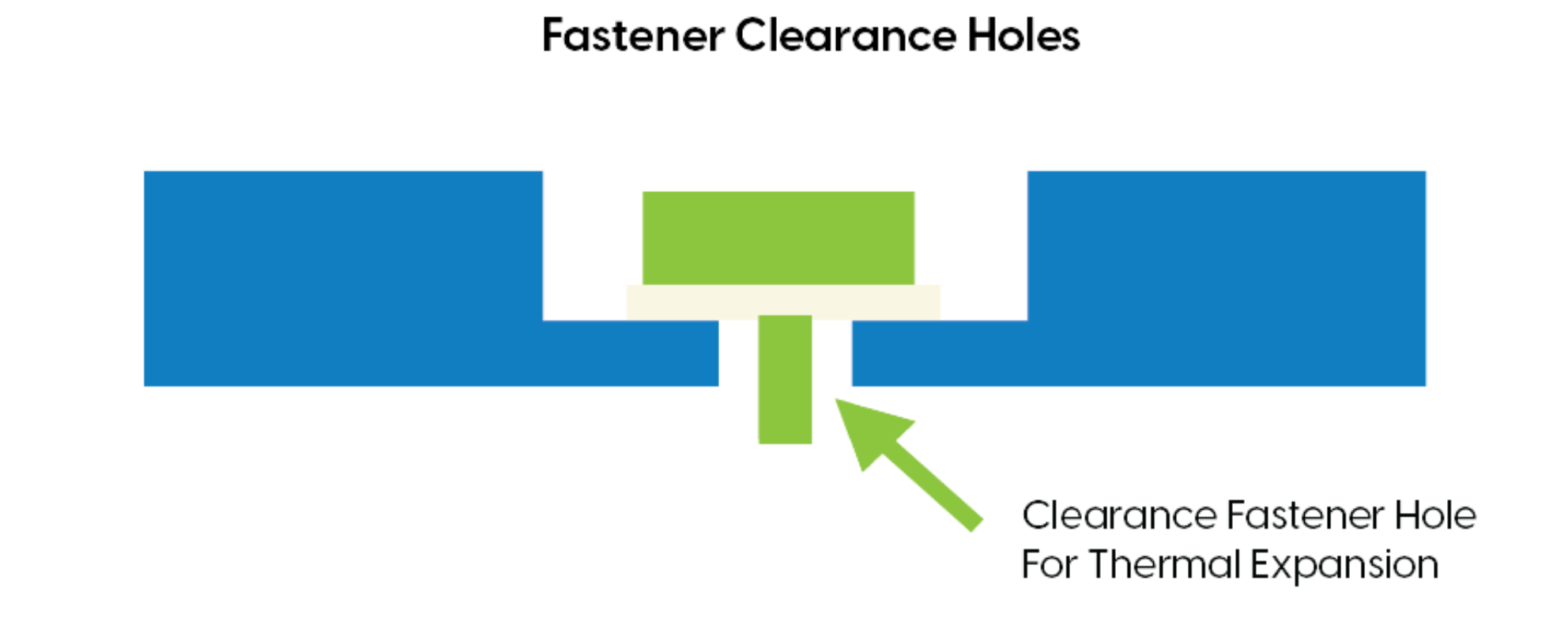

- To determine the gap width, please use the above table as a guide.

- To minimise the gap width, reduce the span length by adding additional expansion joints.

NOTE: There is no one-size-fits-all solution, as every application is unique; as such, design and installations considerations vary. Understanding the principles of designing with material properties in mind is an important element. For further assistance, Dotmar has qualified engineers that can provide technical support and guidance to help you tailor a solution to meet your individual needs.