There is a common view or concern that nylon, which is the common name for polyamide, can’t be used in applications in wet environments or conditions as the material will swell and the dimensions will change to the point that the final part will fall outside of allowable tolerances. Even though nylon does absorb moisture the process is very slow under normal conditions.

Water absorption takes a long time

Time to saturate 20mm thick cast nylon 6 (Ertalon 6PLA) continuously and completely submerge in water at ambient temperature

15.6 Years

After 10 months of continuous and complete submersion of cast nylon 6 (Ertalon 6PLA) in water at ambient temperature

Depth of saturation = 2.3mm

What does water absorption look like?

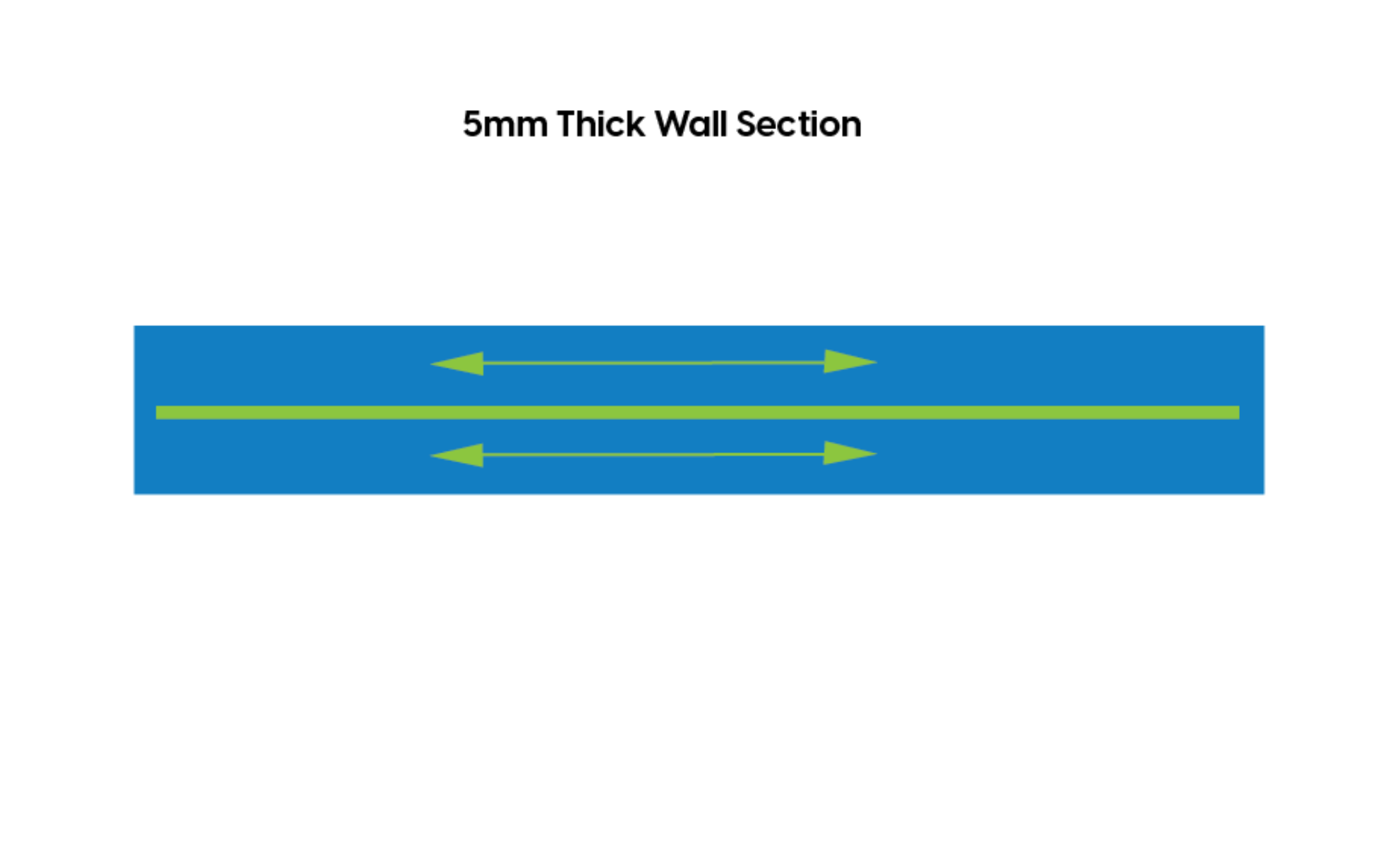

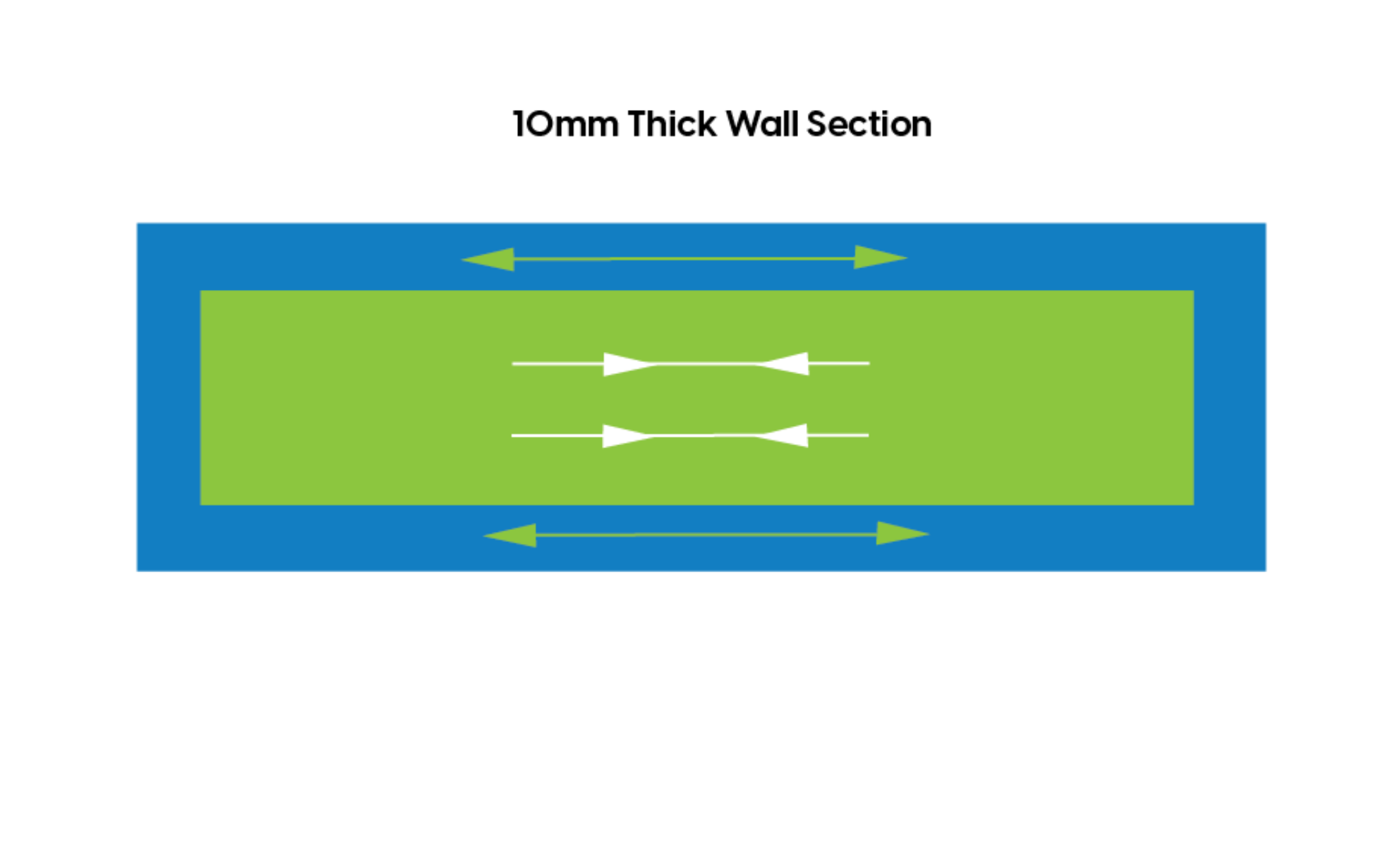

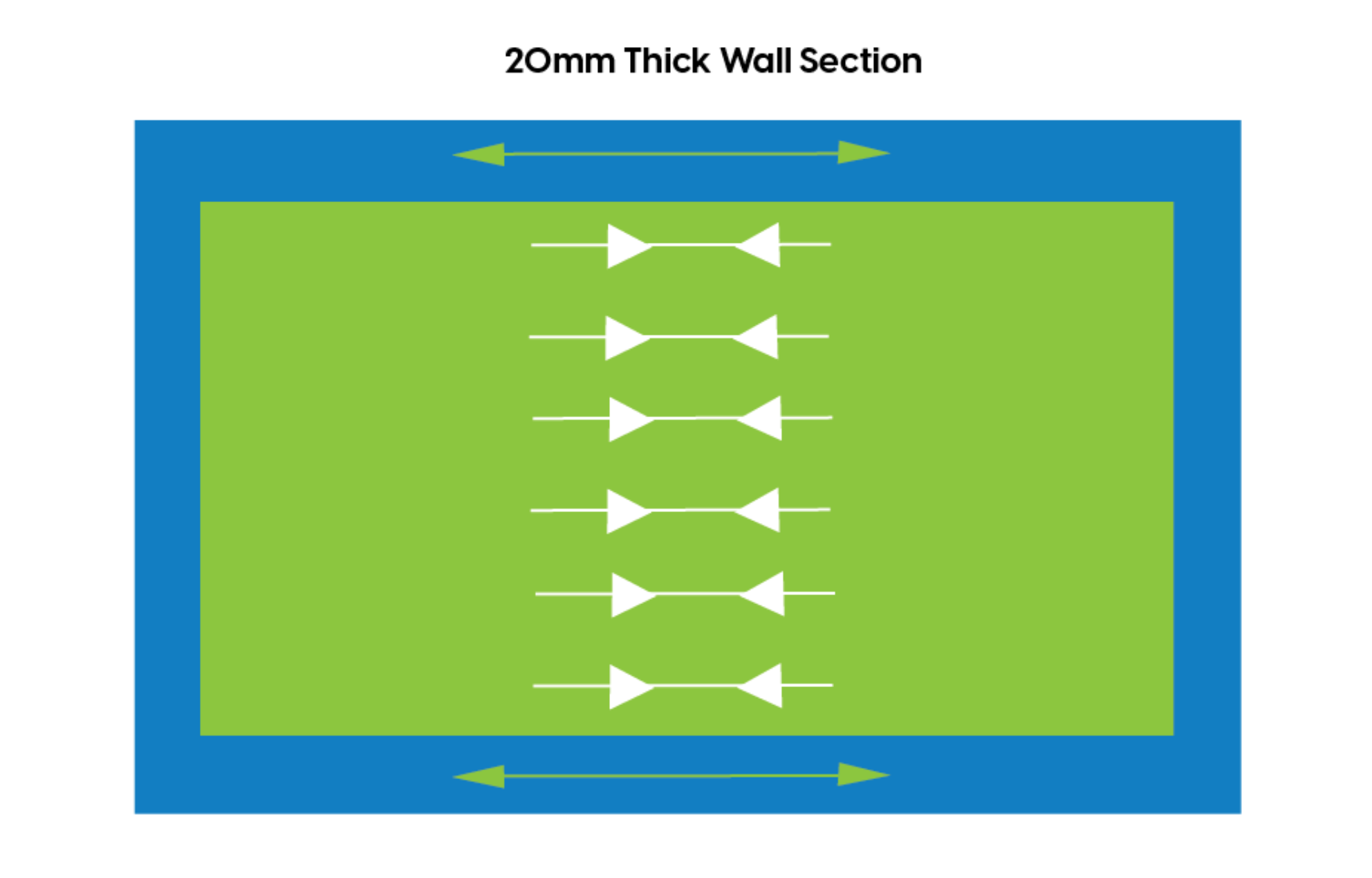

The below illustrations are based on constant and full submersion of cast nylon 6 (Ertalon 6PLA) in water at ambient temperature and for a constant period of 10 months.

*The Blue section represents water absorption to a saturated level

The majority of the thickness of the 5mm thick wall section is saturated, and therefore the material will expand due to water absorption

Less than half of the thickness of the 10mm thick wall section is saturated, therefore the forces to expand the material are balanced by the unsaturated material that helps to hold back the material growth

Only the skin (in comparison to the overall thickness) is saturated, therefore the expanding forces of the skin are not adequate to overcome the non-saturated material that maintains the material or part size.

What does this mean in practice?

When using nylon in wet environments or when submerged in water the “Rule of Thumb” is as follows

- Up to 5mm wall thickness - generally expansion due to moisture absorption should be taken into consideration.

- >5mm to 10mm wall thickness – sometimes expansion due to moisture absorption should be taken into consideration.

- >10mm wall thickness – generally expansion due to moisture absorption is not a factor that needs to be considered.

Generally, nylon can be used in wet environments or submerged in water, even in thinner wall sections, if the allowance for expansion is taken into consideration in the design of the component, just as thermal expansion is considered as a factor for plastics in fluctuating temperature applications.

Benefits of Moisture Absorption in Nylon

The impact and toughness doubles for the skin of the material where the absorption has taken place. This characteristic is advantageous in the way that is minimises the risk of cracking, which normally is initiated at the surface of materials or parts, in tough and high impact applications such as gears, rollers, sheaves/pulleys and Pile Driver Cushions. Note in Pile Driver cushions we don’t use standard nylon, but a modified formulation of nylon.

Conditioning

The promotion of moisture absorption can be accelerated in a process called “Conditioning”, which is different to “annealing”. The Conditioning process must be done under controlled parameters to ensure that the material is not damaged, as well as achieving the required level of moisture absorption to gain the desired benefits. Dotmar has the Conditioning equipment that allows this process to be carried within the required parameters.

For help in material selection and part design for applications in wet environments, please contact one of our eight branches throughout Australia and New Zealand to have one of our engineers provide assistance