Thermoplastic tanks are widely utilised for storing liquids, chemicals, and other materials. However, the fabrication process of rectangular tanks often poses challenges in terms of structural integrity and assembly efficiency often without reinforcements that are often required to be made from steel. Enter Polystone CubX, a revolutionary material that has transformed the way rectangular plastic tanks are designed and manufactured.

Polystone CubX

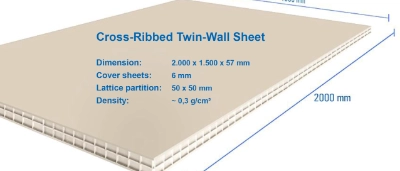

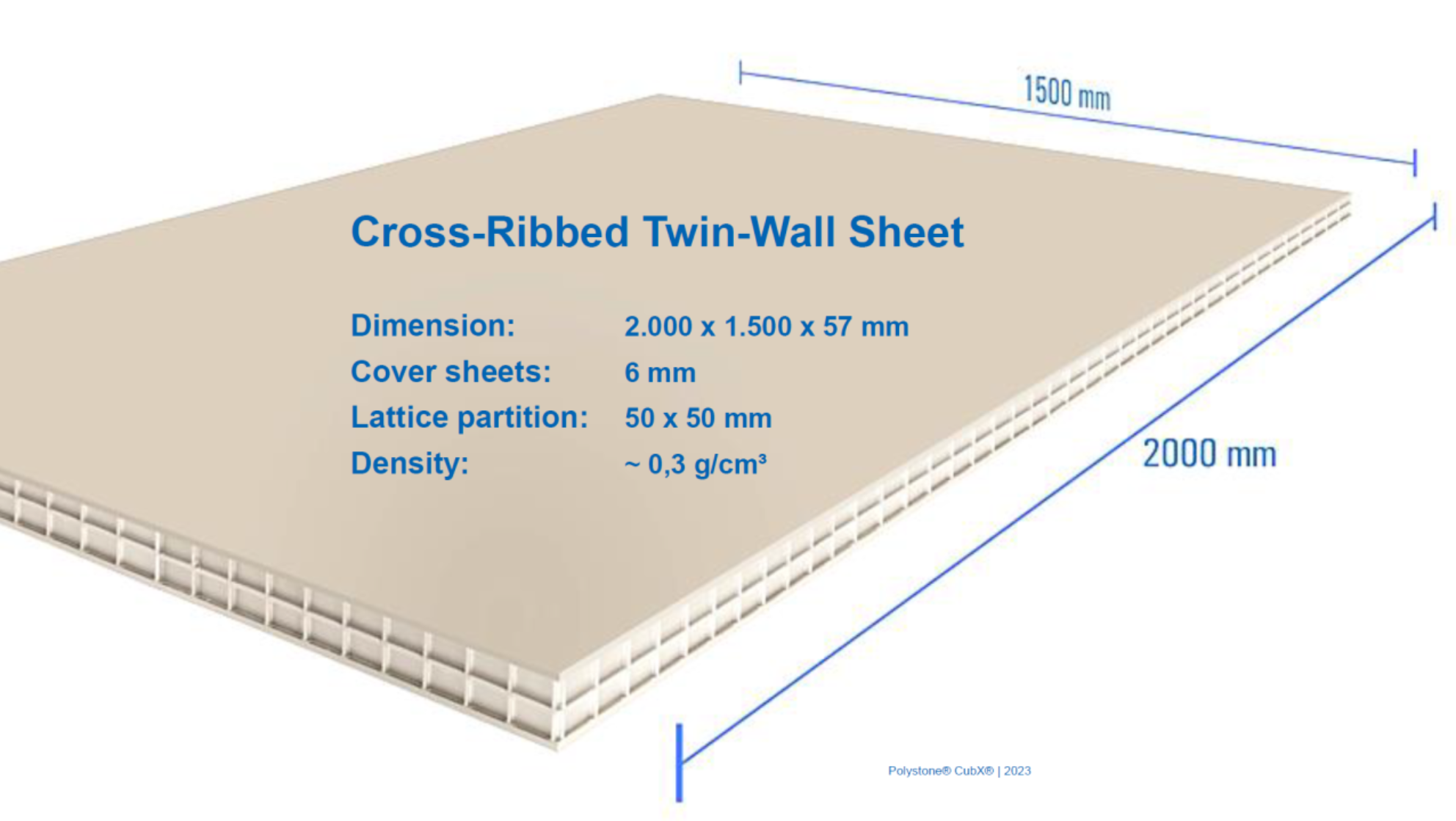

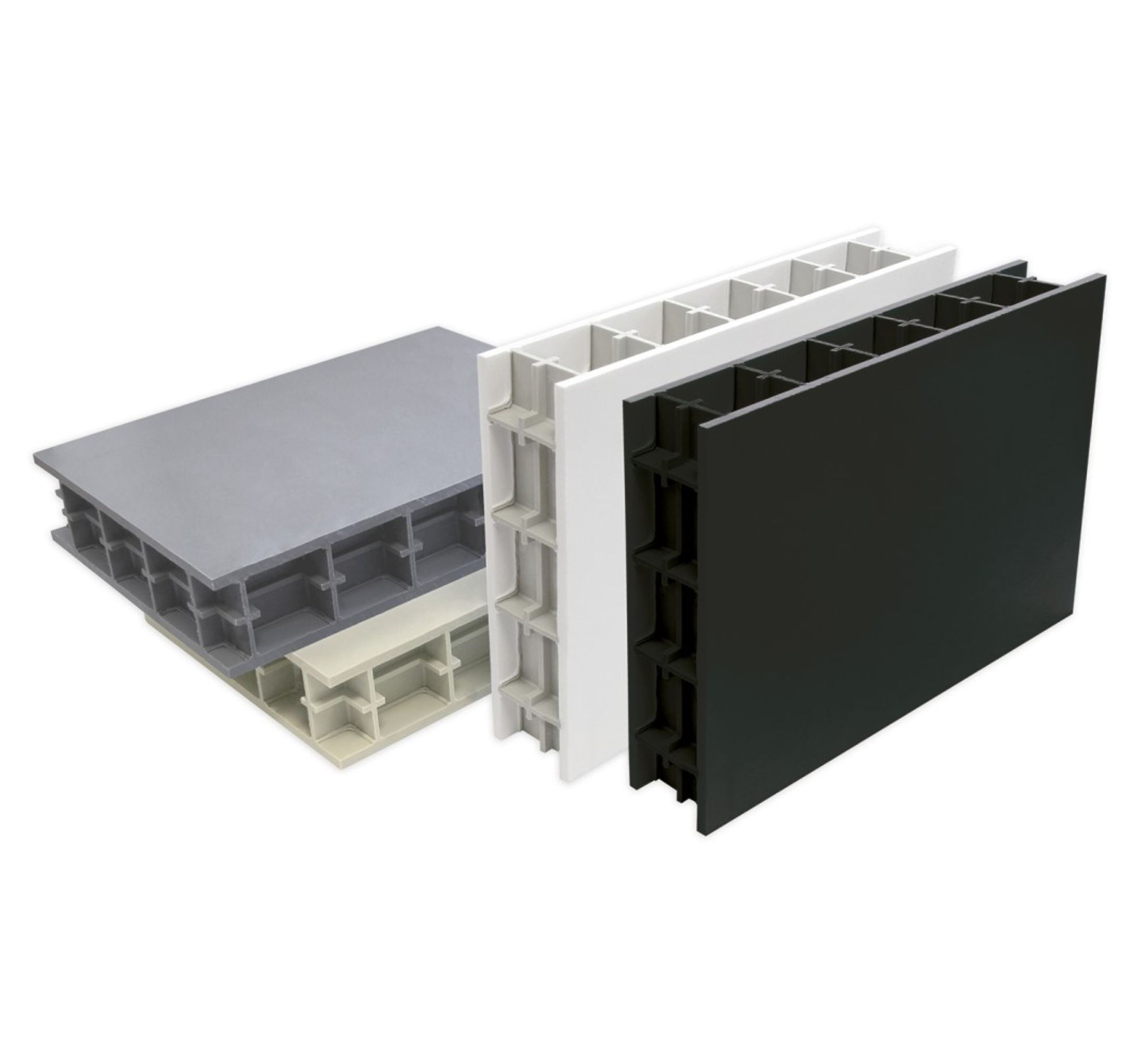

Polystone CubX is an innovative sheet made from both high-density polyethylene (HDPE) and polypropylene (PP) developed by Röchling, a leading provider of engineering plastics. What sets Polystone CubX apart is its unique structural design. It features a grid-like reinforcement structure, which provides exceptional stiffness and rigidity to the material. This design allows for the fabrication of large, rectangular tanks without the need for significant supporting structures that are the norm for traditional solid sheet tanks.

An ideal application for Polystone G CubX is illustrated by this 6000 x 2450 x 1500mm tank manufactured by Corey Knowles of Plastico and Hackett Engineering Australia (www.phengineering.com.au) where a combination of both CubX and solid sheet were used in the construction. The higher stiffness of the Polystone G CubX on the walls (compared to solid sheet) allowed minimal steel reinforcement.

This resulted in

- Reduced weight that allowed for easier handling & reduced shipping costs.

- Lower total material costs

- Reduced manufacturing time and man hours

Advantages of Polystone CubX

CubX is stiffer than the same material in 35-40mm (depending on the grade) but half the weight, which is advantageous with regard to handling, shipping and Work Health & Safety.

Polystone CubX complies with the DVS tank building standards, which are now included as part of the Australia Standards.

Dotmar Engineering Plastics, with the support of Matthias Klein of Röchling Industrial, can provide FEA and design assistance to ensure that the tank is designed to a safe standard to meet the requirements of your application.