Understanding nylon and water absorption: addressing common misconceptions

Written by Aldo Mostacci, Technical Marketing & Engineering Manager (ANZ) - Dotmar

Since joining the engineering plastics industry in 1995, it has often been said that nylon cannot be used in applications involving water. The concern is that the material will swell and cause fitment issues. However, this fear is often unfounded.

Nylon does absorb moisture, which will affect its dimensions. In over 25 years of working with stock shapes (rod, sheet, tube, etc.) in engineering plastics, there have been only a handful of instances where expansion due to water absorption has caused problems or where nylon was avoided due to potential expansion issues.

The facts about nylon and water absorption

These facts are based on one of the most common nylons used in the Australian market from the stock shapes segment of the plastics industry: Ertalon 6PLA. The amount of water absorbed by nylon depends on the environment (whether it is in the air or continuously submerged in water) and the temperature. When continuously submerged in water at ambient temperatures, Ertalon 6PLA will eventually absorb 6.5% of its weight once saturated. However, it should be noted that reaching saturation can take a long time, especially with thicker walls.

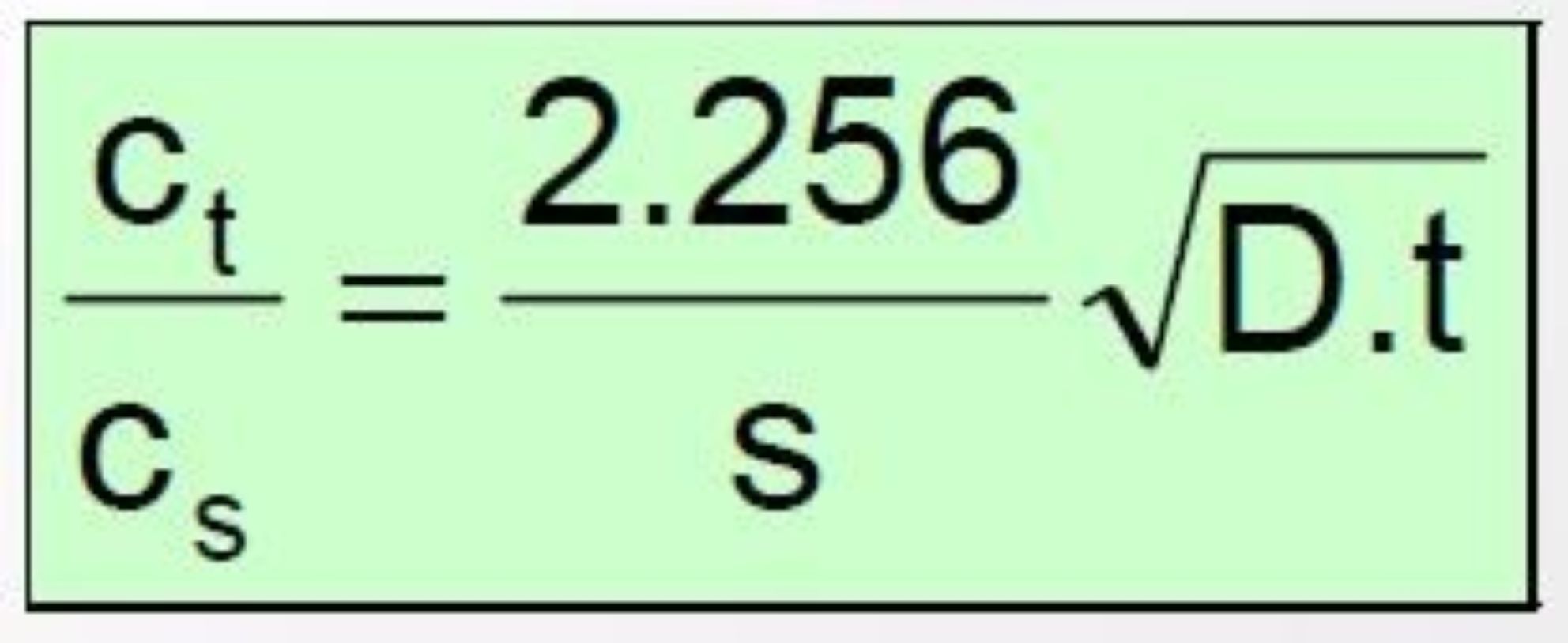

To estimate the time to absorb water or the amount of water absorbed, the formula on the right can be used.

Ct = Moisture content at time t (%)

Cs = Moisture content at saturation t (%)

S = Wall thickness (cm)

D = diffusion rate for the given material (cm2/sec)

T = Time (sec)

The above formula is a conservative estimation, where actual practical tests show to reach saturation when completely submerged in water at ambient temperature

10mm thick Ertalon 6PLA takes 5.9 years

50mm thick Ertalon 6PLA takes 148.6 years

If the part is a wear component, it will likely wear out faster than the expansion rate.

The estimated expansion due to moisture absorption, once saturated while submerged continuously in water for 10mm thick Ertalon 6PLA is approximately 0.2mm.

Rule of thumb

When using nylon in water, when do you take into consideration the potential for expansion due to water absorption?

The answer is based on wall thicknesses

Up 5mm thick: Expansion should be considered in the material selection and design.

>5mm up to 10mm: Sometimes

>10mm: generally not an issue

The advantage of water absorption in Nylon

Water absorption toughens nylon significantly, and since water absorption starts from the surface this is a good way to toughen a component. This is referred to conditioning, which is a process that is done as required for parts that are subject to high impact loads.

Dotmar has conditioning equipment that does this in a controlled fashion as to not cause any degradation. Please DO NOT boil nylon as this will cause a level of degradation.

It is impossible to provide information to cover all applications, so please feel free to reach out to discuss your individual requirements.